Video

Seamless steel raj rau lub hom phiaj siab

| Cov khoom siv | Qhov 37.0 / St44.0 / St52.0 |

| Khoom specification | |

| Khoom siv tus qauv | TIAB SA 1629 |

| Kev xa khoom raws li txoj cai | |

| Cov khoom tiav pob | Hlau siv hexagonal pob / yas zaj duab xis / woven hnab / sling pob |

Cov txheej txheem tsim khoom

Lub cev tsis muaj zog

Kev tshuaj ntsuam xyuas (spectral nrhiav, tshuaj xyuas saum npoo, tshuaj xyuas qhov ntev, thiab kev kuaj macro)

Sawing

Perforation

Kev tshuaj xyuas cua sov

Pickling

Kev tshuaj xyuas kev sib tsoo

Pickling

Lubrication

Kev kos duab txias (qhov sib ntxiv ntawm cov txheej txheem cycled xws li kev kho cua sov, pickling thiab kos duab txias yuav tsum tau ua raws li cov lus qhia tshwj xeeb)

Annealing (NBK)

Kev ntsuas kev ua tau zoo (cov cuab yeej cuab tam, cov cuab yeej cuam tshuam, flattening, flaring, thiab hardness)

Ncaj ncaj

Tube txiav

Kev kuaj tsis muaj kev puas tsuaj (eddy tam sim no, thiab ultrasonic)

Kev tshuaj xyuas cov khoom

Immersion ntawm anti-corrosive roj

Ntim

Lub tsev khaws khoom

Cov khoom tsim khoom siv

Shearing tshuab / sawing tshuab, taug kev beam rauv, perforator, high-precision txias-draw tshuab, cua sov kho rauv, thiab straightening tshuab

Cov khoom siv kuaj

Sab nraum micrometer, raj micrometer, dial bore gage, vernier caliper, tshuaj muaj pes tsawg leeg detector, spectral detector, tensile kuaj tshuab, Rockwell hardness tester, cuam tshuam lub tshuab, eddy tam sim no flaw detector, ultrasonic flaw detector, thiab hydrostatic kuaj tshuab

Cov khoom siv

Cov khoom siv tshuaj lom neeg, nkoj, kav dej, qhov chaw tsheb, thiab kev siv tshuab tsim

Vim li cas thiaj xaiv peb

Peb tsom mus txuas ntxiv txhim kho qhov zoo ntawm peb cov txheej txheem. Nrog kev nqis peev tsis ntev los no hauv cov kab tiav nruab nrab, cov txheej txheem dej moj tej tawg descaling, thiab nruam induction thermal kho chaw, peb muab cov kev daws teeb meem zoo. Peb txoj hauv kev rau kev tsim khoom sib xyaw ua ke peb cov melting, dov, tho thiab ua tiav cov haujlwm, pab kom tswj tau zoo txij thaum pib mus txog rau tag. Peb cov txheej txheem seamless mechanical tubing muaj xws li tho (rotary forging), thermal kho, thiab kuaj thiab ua tiav.

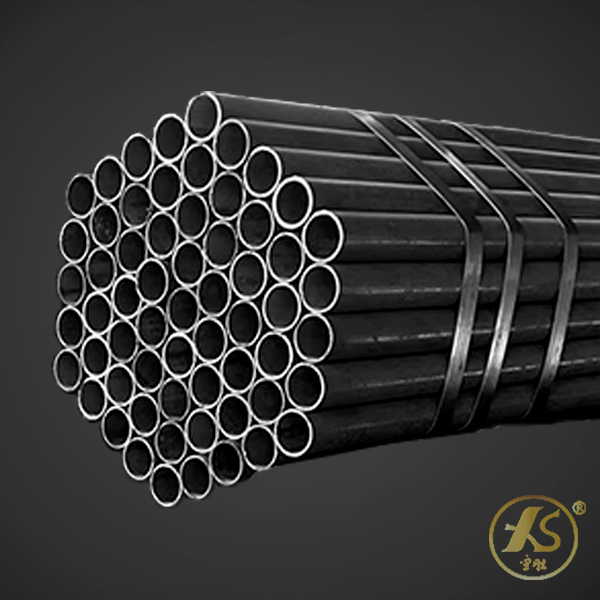

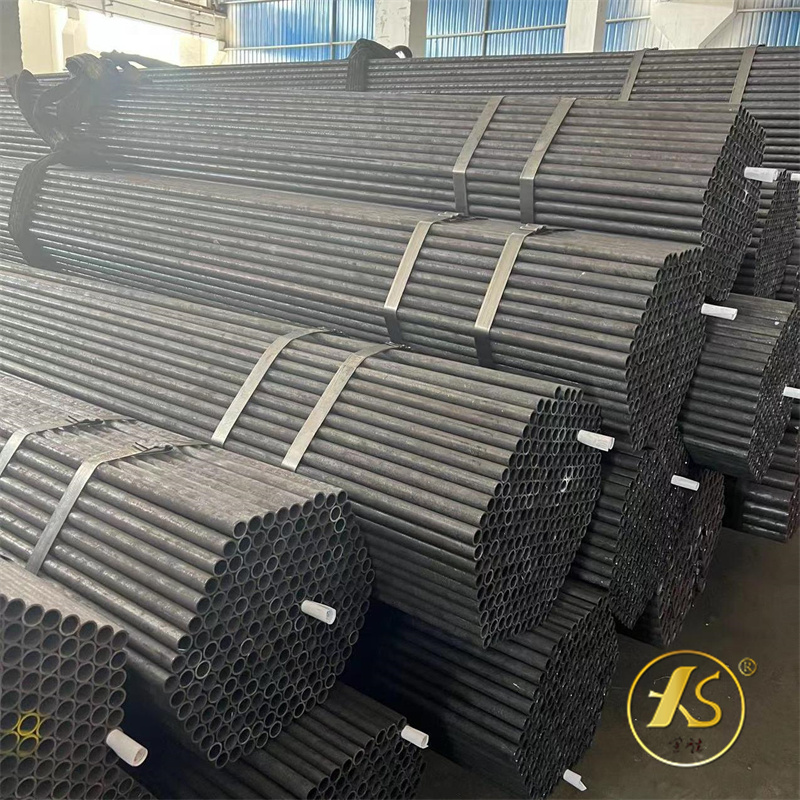

Pob ntawm carbon steel seamless yeeb nkab

Cov kaus mom yas ntsaws ntawm ob sab ntawm cov yeeb nkab kawg

Yuav tsum zam los ntawm cov hlau strapping thiab thauj puas

Bundled sians yuav tsum sib xws thiab sib xws

Tib pob (batch) ntawm cov yeeb nkab steel yuav tsum tau los ntawm tib lub qhov cub

Cov yeeb nkab steel muaj tib lub tshuab hluav taws xob, tib lub steel qib zoo tib yam specification